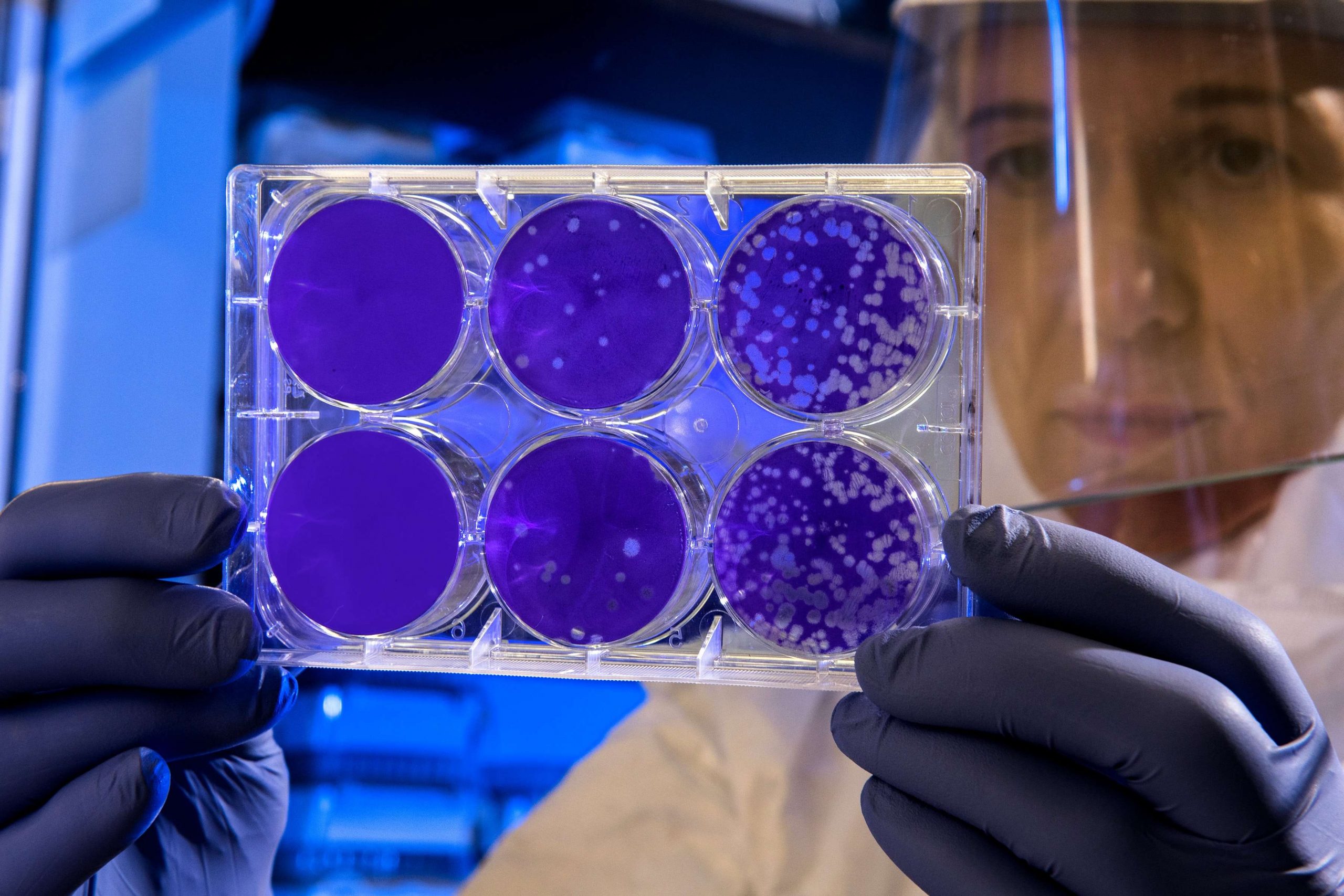

With the development of green energies and alternatives to the use of conventional resources (oil), fermentation processes have a bright future ahead of them.

Thanks to its biotransformation and culture platform and to the expertise of its engineers, TWB (Toulouse White Biotechnology) offers its partners and customers a fully automated high-capacity screening service allowing the implementation of micro-organisms in 24 micro-reactors of 50mL in parallel.

All rights reserved TWB

With the installation of two Fusion micro GCs and controlled channel selectors, the platform now has an unprecedented capacity for online gas analysis on the 24 micro reactors.

The production of light molecules, such as hydrogen, methane and isobutene, is today a major challenge in the energy and transport sectors in the era of energy transition.

Fermentation is one of the production methods used to valorize biomass.

Thanks to the microGC Fusion, the platform is now able to analyze each reactor’s gas production and/or consumption online.

With an analysis in less than a minute per reactor, the monitoring frequency for each medium is about 10 minutes.

Sampling by selection valve allows for an optimal compromise between the number of analyzers needed and the desired analysis frequency per reactor.

All rights reserved TWB

With two identical sets, each including a selection valve and a microGC, the solution proposed by CHEMLYS meets the requirements in terms of size, analysis frequency and budget.

We would like to thank the entire team for their warm welcome and their enthusiasm for the implementation of innovative technologies!