Micro Gas Chromatography (Micro GC) is not a recent analytical technique as we introduced in this article (A Short History of Micro Chromatography). The first publications date back to 1979 and the first Micro GC analyzer was commercialized by the MTI company in 1994.

In 2017, The Micro GC Fusion introduces ultra-fast, independent temperature programming for each of its analytical columns. This is the real innovation that this analyzer technology has been waiting for.

Through this article, we will relive the developments and transformations of Micro CG over time that lead us to this major innovation.

Photo of a Micro GC Fusion equipped with a heated membrane filter at Total’s CSTJF in Pau

First generation Micro GC (90’s)

The first generation of Micro GC in 1994 had many qualities for its time. Its small size and the ability to perform a complete analysis of the composition of a refinery gas in less than 3 minutes imposed a real revolution compared to the traditional laboratory GC. Indeed, the latter is much slower and imposing in size. The use of several modules in parallel brings a speed and a complementarity that the traditional laboratory GC could not compete with. Indeed, a laboratory GC has only one oven. While each Micro GC module has its own isotherm heated column, its injector and its detector

Photo of the first Micro GC marketed in 1994

Photo of the first Micro GC marketed in 1994

Second generation Micro GC (2000’s)

The second generation of Micro GC will keep the qualities of its predecessor by adding modernity and modularity. The user can easily change a module and thus a column to separate other gases and adapt to a new analytical need. This function is very successful and allows more flexibility than conventional GC which allows to change a column without difficulty. As Micro GC is becoming more and more important in gas analysis, it is being compared more and more to the reference technique that remains traditional GC.

Photo of a 2nd generation Micro GC module

New generation (year 2017)

Prior to 2017, Micro GC multiplies modules with isothermal operated columns. However, in Gas Chromatography, an isothermal oven remains a limitation. Indeed, to take full advantage of the separation potential of an analytical column, it must be programmed! Moreover, a programmable oven means that it takes time to heat up during the analysis and to cool down once it is finished. In laboratory GC, it takes several minutes to cool down your oven. This is contrary to the speed of measurement of a Micro GC.

Le Micro GC Fusion overcomes this technical challenge by integrating programmable heating, without increasing the size of the analyzer or impacting the cycle time. The analysis column is wound with a resistive wire capable of heating the column and being programmable in temperature. The column and the resistive wire have a very low thermal mass. Therefore, the cooling of the column and its heating are very fast (from 30°C to 300°C per minute).

Photo of a Micro GC Fusion Module

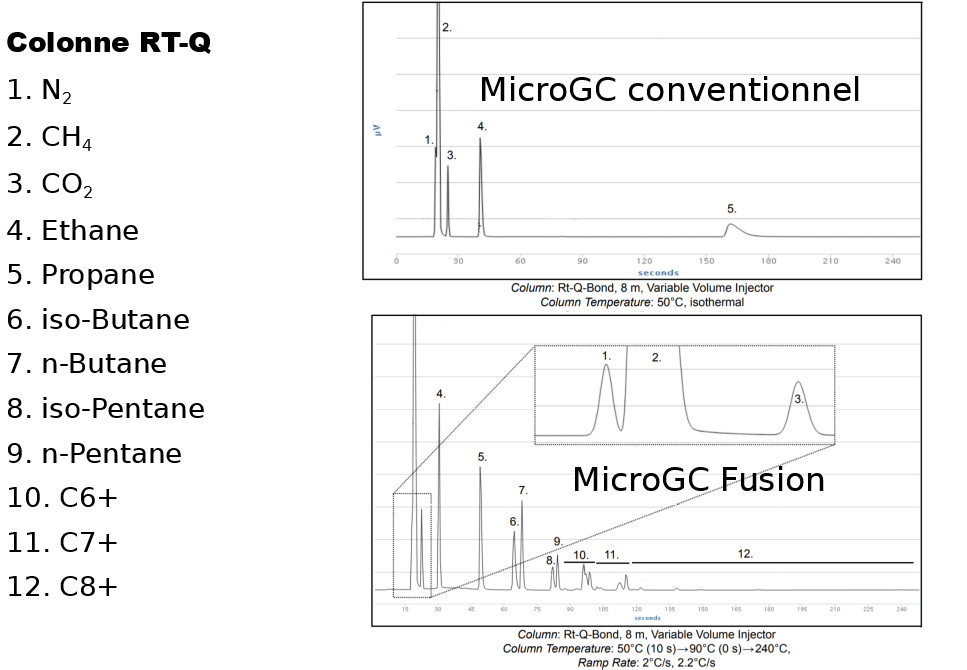

On an RT-Q type column, the isothermal Micro GC is limited to the analysis of C1 to C3. On this column, the Fusion Micro GC with temperature programming allows the measurement of C1 to C8+. And this while keeping a similar analysis time.

Comparison between an isothermal Micro GC and the Micro GC Fusion

Comparison between an isothermal Micro GC and the Micro GC Fusion

Temperature programming has been a standard in laboratory GC for many years. So it was natural that it should be developed for the Micro GC. It was necessary to overcome certain technological barriers and not degrade the qualities of the Micro GC (footprint, analysis speed) at the expense of this improvement.

The application example above perfectly illustrates the enormous contribution of this innovation while maintaining the original performance of the Micro GC.

In conclusion, the Micro GC Fusion represents the real innovation that GC users have been waiting for. It is today the only Micro GC integrating this revolution and pushing the limits of this technology for gas analysis.

The MicroGC Fusion can be found in many fields and applications. In particular for gas analysis in the environment, petrochemistry, biology, quality control, catalysis… Temperature programming opens the door to increasingly complex and efficient gas analysis. Its simplicity of use makes this technique accessible to anyone.

See you soon for more examples of applications and the many possibilities of analysis of the Fusion.

One Comment