Temperature programming: optimal performance finally available in Micro GC.

We’ve already seen it in a previous article, temperature programming is a major advance in micro GC. Available on the Micro GC Fusion exclusively, this specification expands the scope of micro GC applications. In fact, it offers the ability to analyze a wider range of compounds.

Optimal sensitivity over the entire chromatogram

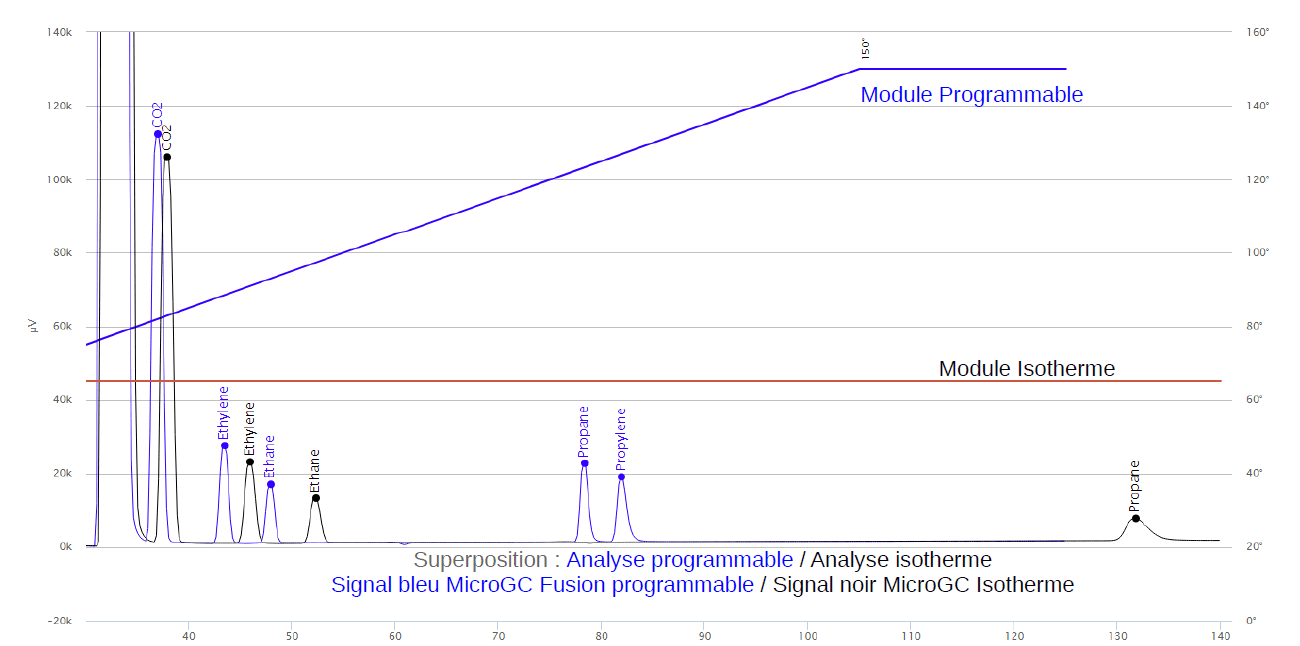

Applying a temperature ramp during chromatographic analysis allows optimization of analytical parameters to the set of compounds being detected.

Thus, in a complex mixture and for a given column, some compounds require a low column temperature to ensure their separations; while others require a higher temperature to guarantee the most punctual elution possible and ensure a fine peak by maximizing its signal to noise ratio.

In isothermal, the user must resolve to determine a temperature that represents a compromise between the lightest and heaviest compounds. See it may be necessary to add an additional module to cover the whole range of compounds.

Thanks to the temperature programming, we now have optimal conditions for the entire working range of the column.

Temperature programming results in improved performance :

-

un sensitivity gain for the compounds eluted at the end of the chromatogram by a conservation of the chromatographic performances

-

Improved peak resolution that results in simplified integration and makes its operation much more robust over time

The image above is a comparison of the same sample analyzed on the same analyzer, once with an isothermal method (in black) and once in temperature programming (in blue).

Proven stability over time

Another benefit of temperature programming is the time stability of the analyzer. This is true and notable primarily for the Molecular Sieve and PLOT columns. These columns, adapted for the separation of the smallest molecular species such as permanent gases (H2, O2, N2, CO, CH4, CO2), are sensitive to humidity (H2O) and heavier species (hydrocarbons).

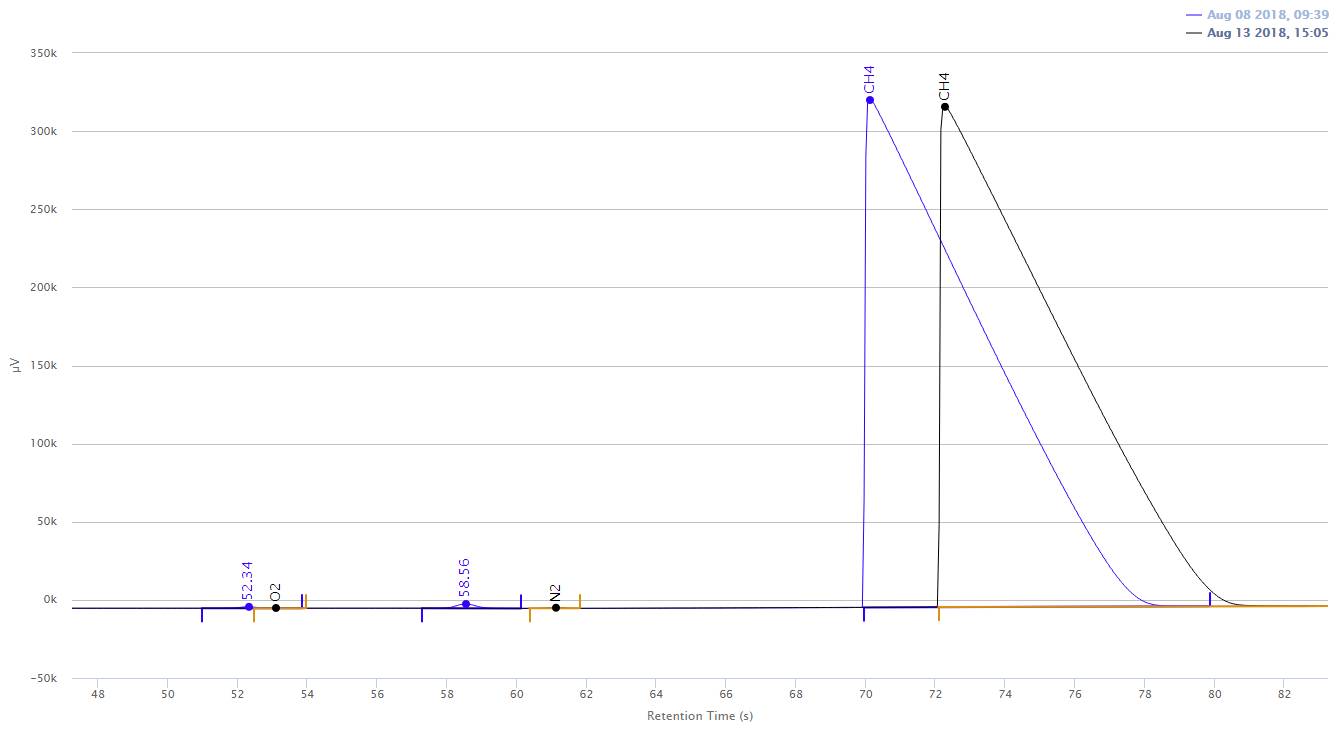

Over time, in isothermal conditions, the accumulation of heavy species or moisture loads the column and the retention times change. As a result, the stability of the analyzer over time is compromised.

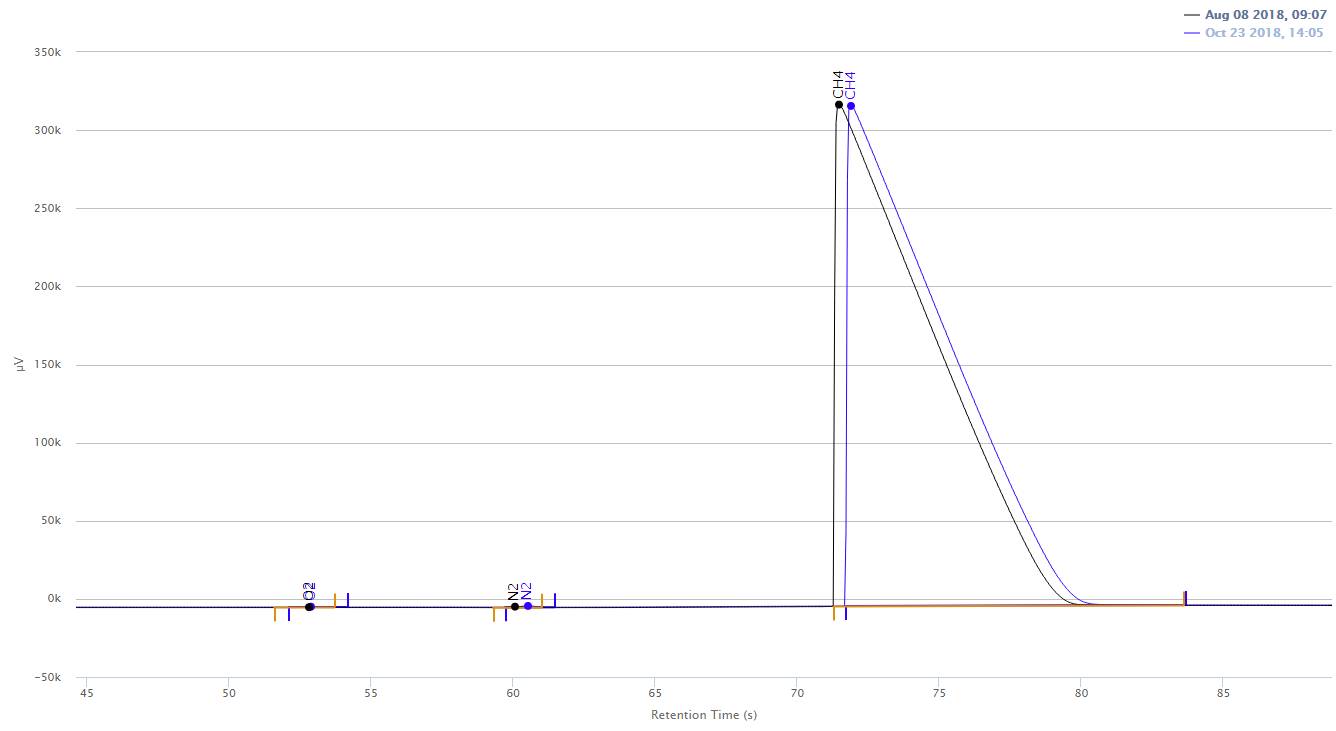

Temperature programming overcomes this limitation. Indeed, by applying temperature programming to each analysis, moisture and heavy species are eluted at each run and therefore do not accumulate in the column. The micro GC Fusion therefore ensures stable results over time.

Continuous biomethane analysis on molecular sieve with a isothermal method.

A significant shift in retention times is already observed over 5 days. It is thus very difficult with an isothermal method to ensure good chromatographic performances and a good stability of the apparatus in time.

Continuous biomethane analysis on molecular sieve with a temperature programming method.

Thanks to the temperature programming applied at the end of the analysis, the micro GC Fusion allows the removal of moisture and pollutants from the column at each analysis. This prevents their accumulation. Thus, we note a shift of retention times in time much lower over more than 2 months.

The stability of the analyzer is important for continuous measurements in an industrial environment, as it ensures the availability of the analyzer.

Keywords: micro gc fusion, temperature programming, biomethane, permanent gas